A workstation with PML-PAL stationary precision air chucks

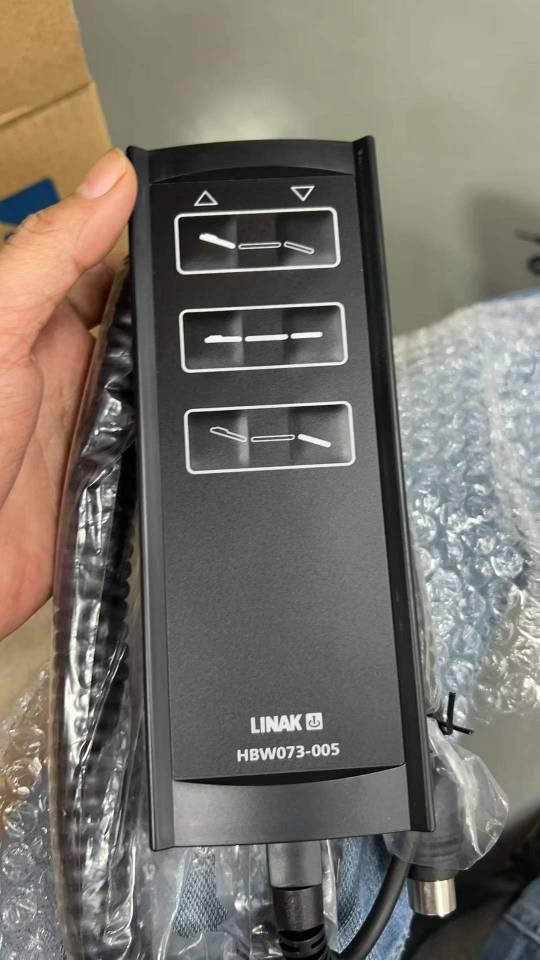

Here is a great example for usage of stationary air chuck in a unique workstation.

A customer has created a cost-effective workstation for honing operation using a robot. There are five stationary air chucks installed on the table. See photos.

The customer is using PML-PAL stationary air chucks 83-3-2.5 TH-12.

The chuck features are:

83mm diameter

Three jaws

2.5mm stroke on Dia.

12mm through hole for boring the workpiece deep in the chuck

Total gripping force 400kgf in 6bars

Stationary air chuck 83-3-2.5 TH12

More information is available @ Stationary Air Chuck With Through Hole

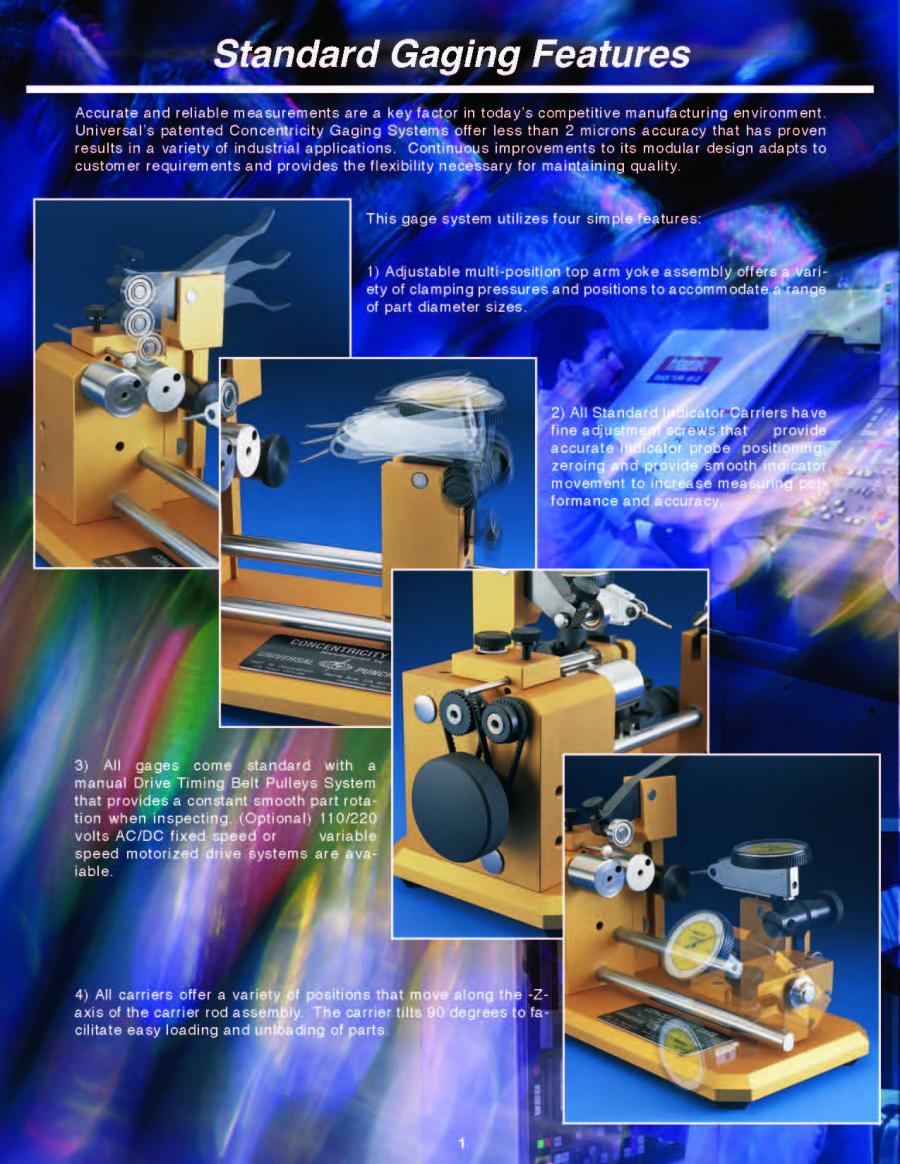

Clamping and milling a small workpiece in one operation

Situation

That is a small workpiece 7.5mm long by 7mm diameter. In the production plan, it was directed to machine it in two operations, meaning two clamps, set-up twice. The first one is for milling the front section and the second is for the back section.

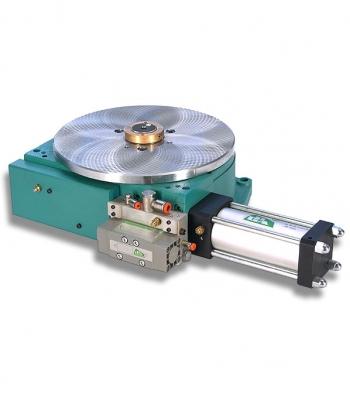

Solution

It was decided to use a 4” air chuck mounted on a 4th axis (rotary table). The CNC operator machined the soft jaws to fit into the back of the workpiece, ID clamping in the 5mm hole (see photo). When the chuck is in an open position, it clamps the workpiece allowing tools access from both surfaces.

Results

The milling operation is done by one clamping, savings the extra handling (set-up) of the workpiece loading and unloading for the second operation. No need to orient the workpiece for the second operation. Needless to say that one operation is always better and more accurate than two.

Double diaphragm high precision chuck

Situation

European CNC grinding machine manufacturer was using two diaphragm chucks for two different operations. The customer used one diaphragm chuck (DC) for grinding the first operation inner diameter (ID), outer diameter (OD), and face. Then he used another diaphragm to grind the three dimensionas on the other workpiece side. The total grinding time was 55 seconds. The customer approached PML-PAL engineering to provide a more efficient solution.

Solution

Our experts came up with an unusual clamping solution, the PML-PAL double diaphragm chuck, an open double-sided chuck that holds the work piece from its core. The chuck is mounted on a unique open spindle made by the customer that allows the customer to grind the work piece’s ID, OD, and face on both sides simultaneously.

Results

The duoble diaphragm chuck design required extensive engineering time and high level of creativity. The custom solution cut the cycle time by 50% reducing the process to one operation thus achieving higher quality product.

Side view of double diaphragm chuck.

Front view including the inner double jaws.

Long clamping solution precision air chuck

Situation

An automotive parts manufacturer approached PML-PAL engineering with an unusual work piece shape (see photo). Due to its unique geometry, it was impossible to clamp it one time to complete the machining job. The customer held it in a conventional way on the outer diameter for the first operation, then on the inner diameter for second one, using two machines. Total machining time was two minutes.

Challenge

The work piece was going to be mass produced and a robot needed to be integrated in the loading process. There was a need to come up with one clamping solution to overcome those challenges and reduce time.

Solution

PML-PAL engineering using newer methodologies, worked closely with the customer to design a unique chuck that clamped the work piece from the long inner diameter. The solution provided a long clamping system to support the work piece from both ends and hold it stable far from the chuck's face. The chuck provided one clamping solution that allowed the customer to finish the part in a single machine.

Results

The customer is now able to produce parts continuously without human intervention. The process is completely automated. The chuck is able to spin at relatively high speed of 2000 RPM while turning. It allows an independent robot to access the work piece to replace it with another for continuous operation. The PML-PAL solution cuts the process to one operation in one turning machine and reduces the total machining time to one minute. Overall, the savings is approximately 50%. As a result of their high satisfaction with this job, the customer asked PML-PAL to produce two more identical chucks for two additional machines. Today, the plant runs three machines, three shifts, 24/6.

Sealed Air Chuck Solution

Situation

A company which produces silicon carbide parts grinds their work piece at the inner and outer diameters. Silicon carbide is a very aggressive material and when grinding, it creates a lot of metal powder that accumulates in the chuck and also sends mist in the air. Using a competitor's open air chucks, the operation frequently stopped abruptly due to dirt in the chuck. The customer often had to dismount the chuck for clean-up and repairs, which created many delays. The organization approached PML-PAL to provide a more sustainable solution.

Solution

PML-PAL engineering offered a stock item, a special sealed chuck model 157-3-2.5 BCG, which is 157mm diameter, three sliding jaws to clamp the concerned work piece. This chuck has a sealing mechanism that does not allow any metal dust or swarf to penetrate it.

Results

Since the customer installed the PML-PAL sealed chuck, they have been running nonstop and have never stopped the operation for dust clean up. Productivity has increased substantially with the absence of unpredictable work stoppages.

Here is a great example for usage of stationary air chuck in a unique workstation.

A customer has created a cost-effective workstation for honing operation using a robot. There are five stationary air chucks installed on the table. See photos.

The customer is using PML-PAL stationary air chucks 83-3-2.5 TH-12.

The chuck features are:

83mm diameter

Three jaws

2.5mm stroke on Dia.

12mm through hole for boring the workpiece deep in the chuck

Total gripping force 400kgf in 6bars

Stationary air chuck 83-3-2.5 TH12

More information is available @ Stationary Air Chuck With Through Hole

Clamping and milling a small workpiece in one operation

Need to machine the workpiece on the right into a finished one like the one on the left side

That is a small workpiece 7.5mm long by 7mm diameter. It was required to machine the workpiece on the right side into a finished workpice on the left side. In the production plan, it was directed to machine it in two operations, meaning two clamps, set-up twice. The first one is for milling the front section and the second is for the back section.

We descided to use a PML-PAL precision air chuck and finish the workpiece in one operation. In order to read more, please refer to the following link: One operation clamping

This is a PML-PAL two jaw 107mm sealed chuck for grinding applications with an air swivelling unit and a 12mm through hole. The chuck is based on PML-PAL 107mm BCG model. The swivelling unit replaces the air feed tube in a machine without through hole in it’s spindle OR in case there is a need to load the workpiece from the front and the back as well. (chuck with three jaws is available as well.)

Technical features:

- Accuracy 0.002mm

- Gripping force 490kgf

- Stroke on Dia. 2.5mm

- Max speed 3500 RPM

- Through hole 12mm

Front view of the chuck without top jaws

This is Model 150-3-12DB a 150MM draw bar precision chuck that provides 12MM stroke on Diameter

Main features:

- Accuracy is 0.006MM or 0.00024″

- Maximum pull force 600 kGf

- Gripping force 1150kGf

- Max R.P.M. is 3500/min

The following fixture is a complete custom-made solution that was designed for an automotive customer. This state-of-the-art fixture has several important features that PML-PAL offers in order to boost operation cycle efficiency.

Advantages of using a precision air chuck fixture is the ability to work on

multiple work pieces simultaneously, hence cutting cycle time substantially (tool changing time saved is roughly 75%). Using our safe and reliable fixture enables easy installation and set-up, quick and easy loads and unloads of the work pieces, and most importantly, a high level of accuracy.

The fixture includes solid aluminum plate base, four (4) PML-PAL 150MM or 6″ dia. stationary precision air chucks, custom hardened top jaws, height stoppers, orientation pins, compact and hidden air tube layout, and a safety stop valve for each chuck. Hosing layout is routed under the plate for the chuck’s jaws actuation.

Professionals in the machining world are debating whether to use hermetically sealed precision air chucks over regular ones in grinding operations. In short, this is because grinding operations create a powdery metal dust or mud that penetrates the chuck’s moving parts and accelerates wear and tear.

Over the years in the precision chuck business, we have had various discussions with customers regarding the subject. There is always a debate as to whether to use a sealed air chuck for grinding applications or keep using unsealed chucks.

Some customers tend to purchase more than one chuck. They work with one and have one on the shelf for replacement when the first one is off for maintenance. When metal powder slowly penetrates a unsealed air chuck, it accumulates in the chuck body between the master jaws and its tunnels. Over time, the inner working parts erode and the chuck loses its accuracy. One way to extend its life, is to stop operation every so often for cleaning and maintenance. This is a non-productive period that of several hours of what would have been productive machining time. In addition, we need to take into consideration the personnel time used for maintenance efforts.

The sealed air chuck offers higher productivity, and the quality of continuously working with one chuck. A sealed air chuck requires minimum maintenance – once-a-month lubrication. The unique design prevents penetration of any swarf or metal powder into the chuck, minimizing or almost eliminating maintenance or stoppage time. This means that the machine does not stop for chuck maintenance.

The “myth” of the sealed chuck is that people don’t believe that it is worth the extra cost. Yet little by little the cost of an unsealed chuck can build to a point where the difference could be nominal. It is a fact that the cost of a sealed air chuck is substantially higher than an unsealed one. It is a superior chuck with additional parts and several heavy duty sealants. The sealed chuck does not require having a spare one on the shelf and it needs only frequent basic lubrication. When choosing a chuck strategy, management must weigh the higher price of a sealed chuck against the cost of owning a spare and the loss of production time and personnel hours when conducting maintenance on the unsealed version. A sealed chuck will work continuously for several years and keep its accuracy for longer period of time. Having all the facts before you buy is essential, then with it you can make a careful analysis of what is the most valuable return on investment for your business.

Henri Azaria PAL Ltd. is the maker of PML-PAL high precision pneumatic chucks. We also make other types of chucks like precision manual chucks, draw bar chucks, sealed precision air chucks and custom made chucks andfixtures per customer specifications. Most chucks we make are high precision air chucks with clamping accuracy of 0.002MM. Diaphragm chucks are super high precision at 0.0005MM or 0.00002″.

Henri Azaria PAL was founded in 1969 by Mr. Henri Azaria. Mr. Azaria started as a, small one man show, sub contractor making parts with a few machines in a very tiny shop. Today the company is global, selling high precision air chucks around the world. The chucks are sold in four continents and we are looking to expand.

Being a contract manufacturer for so many years has taught us the advantages of working with precision air chucks vs. manual vice or other clamping tools. I will not discuss this subject right now. However, I will make sure to post a comparison between stationary air chuck and a vice soon. I know there is always a debate regarding pros and cons of each one of those tools. I will bring up some photos as well discuss the difference. Please look for my future publications.

For more information, please visit www.pml-pal.com

Draw Bar Rotating Precision Chuck

On this page pml-pal presents several draw bar precision chucks with different configurations and sizes.

Draw Bar operated chuck actuated by either air or hydraulic back cylinder. The chuck in the following photo 80-3-5 DB Model is small with several characteristics: it is only 80 MM DIA. with a large through hole 19MM. Designed to be used in small size CNC lathes and sub-spindles.

Main features:

- Repeatability is 0.005MM or 0.0002"

- Jaws stroke on DIA. is 5MM or 0.2"

- Maximum Draw Force is 600 kG

- Maximum Gripping Force is 765 kG with top jaws

- Max R.P.M. is 6500/min

- Through Hole 19MM

80-3-5 DB TH 19 Model

|

|

|

| Draw Bar 80MM chuck w/o top jaws |

Back View |

Side view |

Draw Bar operated chuck can be controlled by either air or hydraulic back cylinder. The chuck in the following photo is relatively small, only 95 MM DIA. less than 4" with a very large through hole 26MM.

Main features:

- Repeatability is 0.005MM or 0.0002"

- Jaws stroke on DIA. is 5MM or 0.2"

- Maximum Draw Force is 1250 kG

- Maximum Gripping Force is 2700 kG without top jaws

- Maximum gripping force is 1800 kG with top jaws

- Max R.P.M. is 7000/min

- Through Hole 26MM

|

|

| Back view |

150-3-12 DB Model 150mm Draw bar rotating chuck with 12MM

stroke on Dia.

|

Technical data:

- Accuracy is 0.006MM or 0.00024"

- Maximum pull force 600 kG

- Gripping force 1150 kG

- Max R.P.M. is 3500/min

- 12MM stroke on Dia

|

|

| Back view |

95-3-2.5 DB model, 95mm draw bar precision chuck with 6MM

through hole

|

|

|

| Back side |

150-3-2.5 DB model, 150MM draw bar precision chuck with 6MM

through hole.

|

Quick Change Chuck

Quick Change chuck (QC) - This page presents QC air chuck for turning applications. This design allows the operator to quickly change from one chuck to another and go back to work at the same accuracy with minimum set up time. It is a high precision air chuck with accuracy of 0.002MM or 0.00008".

Usage and advantages:

When there is a need to machine variety of diameters or different work pieces at high accuracy, this configuration offers the ability and the flexibility to quickly remove the chuck along with its top jaws as one piece and change it with another one without dismounting the air feed tube or the adaptor on the machine spindle nose. Thus continue machining the next piece.

The new chuck will provide the same high accuracy. This configuration saves on set up time and minimizes adjustment.

PML-PAL offers Quick Change option in any chuck configuration including diaphragm chuck. Quick change chuck is also known as Back Air Ported chuck. There are two air ports at the back of the chuck.

For long work pieces clamping, it is recommended to order the QC chuck with through hole.

|

|

| Back view. Notice the back air ports. |

83-3-2.5 NBC-Q model, Quick change air chuck 83MM |

|

|

| Back view |

Precision Conical Air Chuck

The conical chuck is a special one that is designed to clamp cutting tools like end-mills, drills, reamers, threading tools / taps in a 5 axes CNC grinding machine. The conical shape allows easy access to the grinding wheel tool. Conical chuck is operated by either integrated air piston or draw bar connected to a back air cylinder.

The need for this chuck arises when a customer approach PML-PAL with a request to have a super high precision chuck with conical front shape which allows the grinding wheel to approach as close as it can to the chucks’ face without hitting it and grind the tool as low as possible (in relation to its cutting edge).

Advantagesof conical chuck:

In the chuck there is a stopper that controls how deep the tool goes in.

Each chuck model can clamp four different work piece diameters (3, 4, 5, and 6MM) by using accurate, quick change insert. Alternatively, in order to cover the whole diameter range, there is a need to use four different chucks.

There are two types of chuck:

- Three jaws chuck – the usage is precision and tight clamping in high RPM (up to 20,000). Can be operated by air or back draw bar pulling.

- Five jaws chuck – the usage is precision tool clamping in CNC grinder. Its’ advantages are using one chuck type to hold several diameters. The repeatability is within Microns MM. Can be operated by air or back draw bar pulling.

This chuck is extremely accurate. Repeatability is 0.0005MM.

This is a three jaw tool clamping high precision chuck

Mechanical Parameters in mm

| Main Body |

Model |

| L |

H |

G |

F |

E |

d |

D |

C |

B |

A |

| 38 |

30 |

M4 |

54.8 |

- |

8.3 thru |

50 |

2 |

75 |

63.5 |

TC 64-3-2 |

| 45.5 |

19 |

M5 |

61 |

- |

10.5 |

50.8 |

2 |

90 |

72 |

TC 72-3-4

|

Technical Parameters

| Max. R.P.M. (r / min) |

Jaws |

Model |

| Total Gripping Force (kgf) - 6 Bar |

Stroke On Diameter (MM) |

No. Of Jaws |

| 15000 |

190 |

2 |

3 |

TC 64-3-2 |

| 10000 |

240 |

4.4 |

3 |

TC 72-3-4 |

This is a five jaw tool clamping high precision chuck

Mechanical Parameters in MM

| Main Body |

Model |

| L |

H |

G |

F |

E inner Dia |

d |

D |

C |

B |

A |

| 27.9 |

55 |

M4 |

54.8 |

2-5 |

12 |

50 |

2 |

73.4 |

63.5 |

TC 64-5-1 |

| 40 |

69.5 |

M5 |

70 |

6-10 |

16 |

60 |

2 |

96 |

82 |

TC 82-5-1 |

| 52 |

90.5 |

M5 |

88.9 |

10-16 |

23 |

82.55 |

2.5 |

119.5 |

101.6 |

TC 101-5-1 |

| 64 |

115 |

M5 |

114.3 |

18-25 |

34 |

101.6 |

2.5 |

147.5 |

127 |

TC 127-5-1 |

Technical Parameters

| Max. R.P.M. (r / min) |

Jaws |

Model |

| Total Gripping Force (kgf) - 6 Bar |

Stroke On Diameter (MM) |

No. Of Jaws |

| 13000 |

250 |

0.3 |

5 |

TC 64-5-1 |

| 10000 |

420 |

0.3 |

5 |

TC 82-5-1 |

| 8000 |

680 |

0.3 |

5 |

TC 101-5-1 |

| 6000 |

Manual Precision Chuck

This is a precision manual chuck with excellent accuracy or repeatability of 0.006MM. Designed to work on any lathe machine.

Max. torque applied on key - 40 Nm

Total gripping force - 2750 kgf

Speed – up to 6000rpm

Weight Without Top Jaws - 5 kg

Repeatability is 0.006MM

Chucking Capacity of Jaw Steps

| External Chucking |

d1 |

d2 |

d3 |

d4 |

Internal Chucking |

D1 |

D2 |

D3 |

| 6...28 |

14…36 |

36…58 |

58...80 |

Single Jaw Precision Air Chuck - Sealed

This is a custom high precision grinding air chuck with a single sliding jaw. The air chuck is designed for a specific customer need. It is hermetically sealed Ø107MM with one jaw that slides 1.5MM. This chuck is based on the BCG grinding model. The chuck is to be mounted on a CNC grinding machine functioning as a spinning air precision vice. All holes are designed per the customer specifications. On the opposite side of the jaw there should be a static stopper.

Repeatability is 0.0015MM.

Gripping force 360 kgf.

107-1-1.5 BCG Model

Air-Spring High Precision Chuck

In this page we are presenting a few examples of air-spring chucks on sealed chuck models.

This is a 107mm special hermetically sealed high precision chuck that operates on air and spring force. It opens via spring force and closes on air pressure. This is a custom chuck that was crafted per customer specifications. It is based on chuck BCG model. It serves the optical industry. It is used for lens grinding and polishing.

Below is 64-3-1.4 RJ model, round master jaws super high precision air chuck. It was developed for specific customer's requirements.

The chuck opens via springs and closes by air pressure. This is a sealed chuck quick change model. It is designed to grind lenses.

The chuck repeatability is 0.0015mm.

64-3-1.4 RJ model, front view

64-3-1.4 RJ model, back view

Jaw Stroke Front Control Chuck

This is a high precision air chuck specifically designed based on customer’s requirements. It is a three (3) jaw, 100mm Dia. air chuck that has the option to adjust its jaw stroke within its range. Based on particular application, the operator can adjust the jaws travel within the stroke range of 0.1mm to 2.5mm.

In case of a small diameter workpiece, there is a possibility to limit the jaws stroke to min. in order to clamp tiny parts and not “loosing” them between the open top jaws.

This adjustment is easily done from the front side of the chuck via a convenient regulator button.

Long Stroke Preceision Air Chuck

The following are precision air chucks with long jaw stroke. The jaw stroke may vary

from 3MM up to 18MM on the diameter. These special long jaws chuck has repeatability

of up to 0.005MM or 0.0002". They may be ordered with 2, 3 or 4 jaws. All models may be applied

for turning, milling and grinding (sealed chucks) operations - static or rotating, verticaly or

horizontaly.

Advantages:

1. Long stroke chucks are mainly used for large clamping range with the same top jaws.

Therefore, saving set-up time. It requires fewer top jaws sets.

2. An option to pass a larger dia. "shoulder" in order to clamp over it (smaller dia.).

3. Two jaw models have the option to clamp "spiral" parts with limited clamping area.

4. Another advantage of two jaws chuck is to load the part from the top jaws side.

5. Accuracy is 0.005mm or 0.0002".

107-3-10 STG model - a long stroke precision air chuck, sealed model with 17MM through hole,

and 10MM jaw stroke on diameter. This is a stationary chuck suitable for milling and grinding applications.

157-2-10 BCG model - This is a long stroke 157MM BCG model precision air chuck, sealed

model with two jaws and 10MM jaw stroke on diameter. This is a rotating chuck suitable for turning and

grinding applications.

150-3-12 DB Model - This is a long stroke 150MM precision rotating draw bar chuck, for

turning applications. This chuck has three jaws and 12MM jaw stroke on diameter.

220-3-18 NBCG model - This is a long stroke 220MM sealed precision air chuck, rotating chuck

for turning and grinding applications. This is a sealed model with three jaws and 18MM

jaw stroke on diameter.

250-3-18 BC model - This is a long stroke 250MM precision rotating air chuck, for

turning applications. This chuck has three jaws and 18MM jaw stroke on diameter.

Mini Precision Air Chuck

This is a mini high precision rotating air chuck with three (3) top jaws suitable for turning applications clamping very small workpiece. The mini air chuck may be mounted on small lathe machine.

Technical characteristics:

- Outer diameter is 50MM or 2".

- Stroke on dia. is 2MM.

- Maximun rotating speed is 6000 rpm with 10MM top jaws.

- Total clamping force is 86 kilogram-force, kGf.

- Accuracy is 0.002MM or 0.00008".

- The mini air chuck weighs 600 grams or about 1.5 Lb with top jaws.

This chuck is a BC model. This size chuck also comes in NBC model and stationary (ST) configuration.

50-3-2.5 BC model with top jaws front view

50-3-2.5 BC model without top jaws front view

50-3-2.5 BC model back view

BC Model – The chuck's piston has an inner movement back and forth together with the air feed tube (AFT). This is a safety feature that is required by CE, the European standard. It allows a slight delay after opening and closing of the jaws, before the machine starts its cycle. When the AFT moves forward, the jaws close/clamp the workpiece. Only then, the machine will receive a green light from the proximity sensor to start the cycle.

NBC Model – The Piston movement is internal only. In this model, coolant is available through the chuck body. The chuck is more stable hence rotate on higher rpm.

|